Department Process Engineering

Recycle of nitrogen and phosphorus at the WWTP Kloten/Opfikon via combined air stripping (full scale experiments) and urine treatment

The central objective of this full-scale project is the further development and optimization of a process for the reduction of the ammonia-load of the municipal WWTP Kloten/Opfikon (nominal size: 54.000 PE; actual load 60.000 PE) from both sludge side-streams and source separated urine by air-stripping. It is expected to stabilize the whole biological treatment, lower the nitrogen effluent concentrations and to reduce the energy consumption of the WWTP. No new waste streams will be generated, since the ammonia is fixed in a marketable nitrogen fertilizer.

Up to 25% of the inflow ammonia-load of a municipal WWTP is caused indirectly by the sludge treatment. These so-called sludge side-streams are a result of an anaerobic sludge digestion and subsequent sludge treatment like dewatering and drying. In recent years, more and more WWTPs have been equipped with facilities for pre treatment of the ammonia rich supernatant, usually to reduce the N-load of the main WWTP lane. Around 10 pre-treatment plants in Europe are using the air stripping process, whereas the other plants eliminate ammonia via nitrification denitrification or anammox.

In addition to these end-of-pipe technologies, an increasing number of waterless urinals were installed over the last years in public and individual buildings (e.g. airport Zurich), which allow to collect ammonia-rich urine, thus reducing the nitrogen-load of the WWTP.

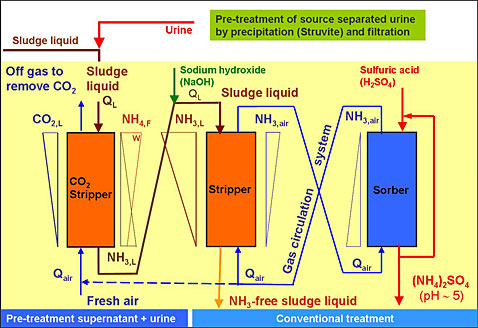

The activities are a combination of advanced engineering with research and will optimize the new, full-scale stripping plant of the WWTP Kloten/Opfikon (the process flow sheet is shown in the figure). In particular, stripping requires large amounts of a base to deprotonate the ammonia. The energy consumption and costs for the base are a significant part of the overall operational costs of stripping plants. Therefore, the amount of NaOH for the stripping process has to be minimized with CO2-prestripping (see figure) and optimal pH and temperature to increase the overall sustainability.

Furthermore, the Eawag will investigate the co-treatment of source separated urine, which is collected at the Eawag office building. It is planned to add the urine after removal of the phosphate by struvite precipitation to the sludge liquid in order to increase the ammonia concentration. If the co-treatment of urine proves to be possible, the efficiency of the whole process will increase further and a feasible way for urine treatment could be demonstrated. As a by-product, the plant will produce ammonia-sulphate, a marketable fertilizer free of any micro-pollutants.

This project is supported by the European Commission under the sixth framework programme (EU project Routes) and by the offices for the environment of the canton Zuerich (AWEL).

In spring 2011 the presented project won the special prize for innovative projects against climate change founded by the Zuerich Versicherung.

Figure Functional principle of free ammonia stripping and sorption with pre treatment of supernatant by CO2 stripping and co treatment of source separated urine